Dimensional control

Dealing with precise measurements for the oil industry?

Working on ships or oil rigs?

GEONET Dimensional Control:

- Accelerates calculation process

- Possible automatization of calculation process

- allows you to avoid errors and mistakes-makes it easier to control calculations

- allows you to estimate the accuracy of the measurements

- each stage registered in LOG file

- export to AutoCAD

We are able to customize our software to your needs.

Possible modifications include:

- System of codes

- Format of raw observations (various instruments)

- Graphical presentation (AutoCad drawings)

- Report content

- Interface

It is possible to supplement the basic version of the program with additional options in network adjustment or additional utility programs if needed in your business.

Would like to know more? For more information please contact us at: geonet@geonet.net.pl

Basic functionalities

Selected, available modules for Dimensional Control software:

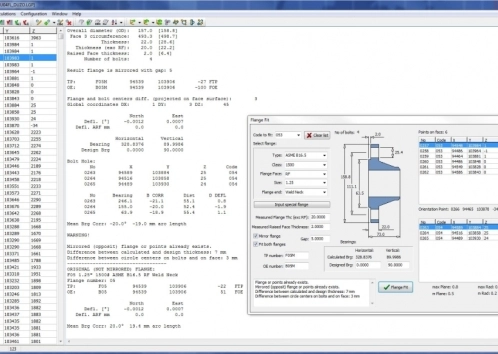

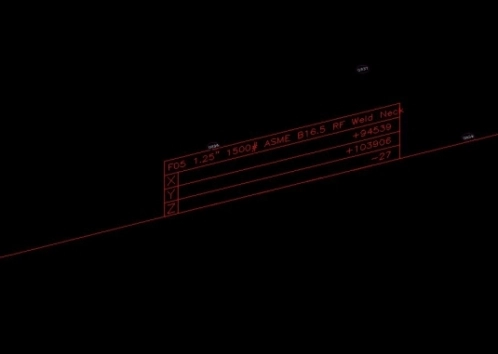

- Flange Fit with database of ASME flange dimensions. Database is editable, more flanges could be added. User can add special, not typical flange during calculations. All deflections (on face and bolts) are calculated and presented.

- HUB Fit (under construction)

- Spool rotation and spool comparison with own design flange definition. Useful, for example, when designed spool is compared with spool made in factory. Least squares method is used when spools are compared.

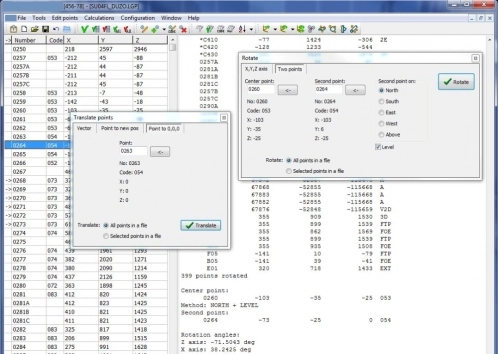

- Rotation of whole setup or selected group of points. Few methods of rotation are possible. Rotation around X, Y or Z axis or rotation around two points (First point is the center of rotation, second is set on the north, south, east, west or above first point. Setup could be leveled during rotation)

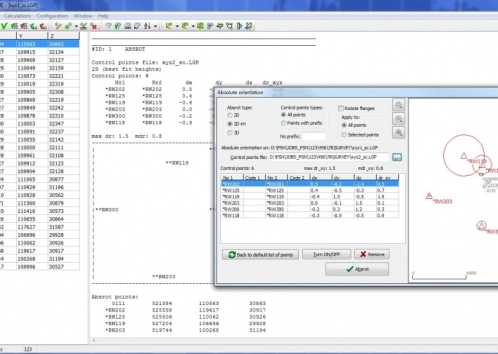

- Absrot (izometrical transformations) of points. Possible various algorithms (2D, 2D+H, 3D). Large amount of control points is allowed (tens of thousands).

- Absrot of many setups in one process – useful when new control points network is created on the object. Ensure consistency of control points which are on setups far from each other.

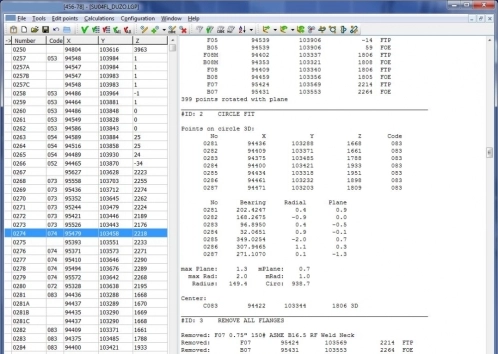

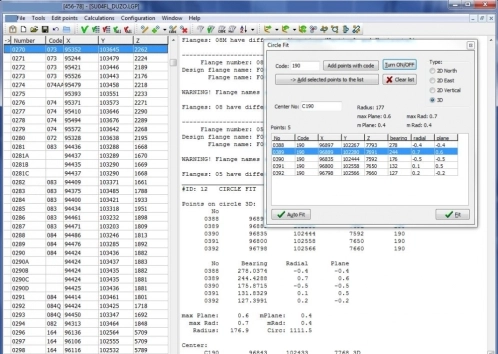

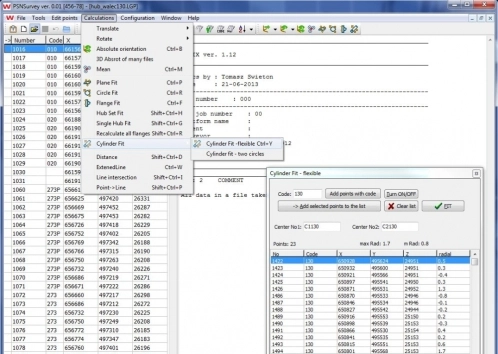

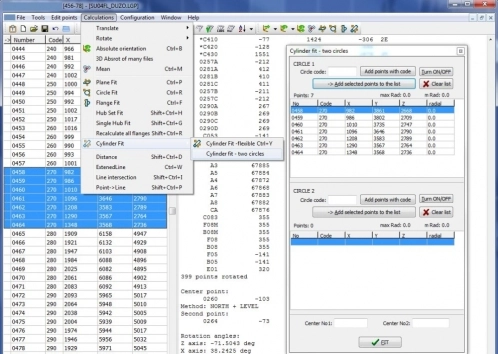

- Fitting of various geometrical shapes: Circle Fit (2D, 3D), Cylinder Fit, possibility of fitting with fixed radius. Fitting of additional geometrical shapes could be added.

- Plane Fit – with leveling of whole setup (Fitted plane is leveled)

- Non contact survey – technology, which provides possibility of accurate measurement of inaccessible (for example: high from instrument) elements, especially flanges. Face’s edges and bolts centers are precisely measured and calculated despite of reflectorless measurement. It provides accuracy higher than with laser scanner – close to traditional methods.

- Transmission of data from instrument. Various file formats from different instruments could be processed. Initial inspection and edition of observations is possible.

- Scripts to AutoCad. Calculation’s results could be presented in AutoCad or another demanded CAD software. All fitted flanges and shapes with deflections could be scripted according to Your needs.

- Calculation of two measured lines intersection using Least Squares method. It finds a point closest to two lines, instead of AutoCad precise method.

- Projection of point on a line (different angle is allowed), calculation of extended line

- Various additional tools: Mean points, calculate 3D distance etc…

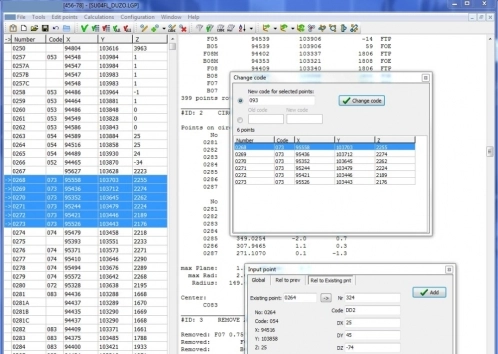

- Edit tools: adding, deleting and editing points and group of points. Various methods of selecting points, various filters, etc...